Forklift Signs-- Affordable Safety Solutions for Industrial Workplaces

Wiki Article

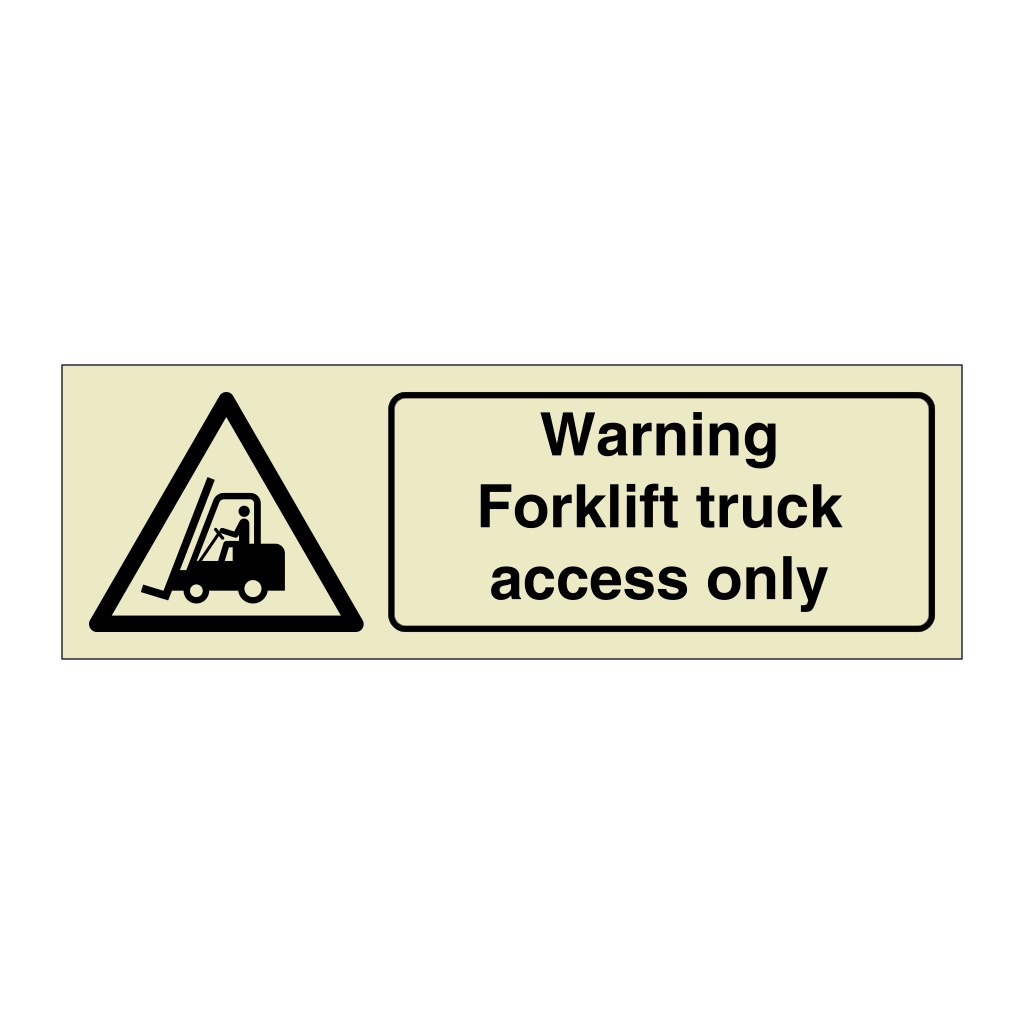

Forklift Safety Signs: Necessary Tips for Optimum Positioning and Presence

Making sure the optimum placement and presence of forklift safety and security signs is critical in keeping a safe and secure industrial setting. Placing these signs at calculated areas such as entry and leave points of filling anchors, crucial facility junctions, and high-traffic storage locations can significantly alleviate accident risks. Placing indicators at eye level and angling them towards oncoming website traffic boosts their performance. In addition, utilizing resilient materials and high-contrast styles guarantees durability and clearness. Understanding the subtleties of regular evaluations and upkeep is just as crucial to promote their capability-- what important steps should be taken to maintain these important security tools?Trick Locations for Security Indicators

Correct positioning of forklift safety and security indications is crucial for preserving a risk-free functioning atmosphere. In addition, placing indications near high-traffic storage areas and blind spots can further boost presence and awareness.Junctions within the center are another vital area where accidents can take place; for that reason, quit signs and right-of-way indications are important. In pedestrian-heavy locations, signs must signal both operators and pedestrians to the presence of forklifts, ensuring every person remains alert.

Areas with high storage space racks and blind areas pose unique obstacles. forklift safety signs. Signage in these areas ought to warn drivers of limited exposure and encourage making use of spotters or extra precaution. By concentrating on these key areas, organizations can develop a safer, much more effective working atmosphere for all

Elevation and Angle Considerations

When mounting forklift security indications, thinking about the elevation and angle of positioning is vital to ensure maximum exposure and effectiveness. Appropriate height guarantees that drivers and pedestrians can easily see the indications without blockage. Usually, safety indications should be placed at eye degree, which is around 4 to 6 feet from the ground. This positioning allows people to rapidly notice and check out the signs as they browse the location.The angle of the indicator is similarly essential. Signs must be angled towards the line of sight of approaching website traffic or employees. For example, if an indicator is indicated to advise forklift operators, it ought to be placed straight in their area of view, ideally perpendicular to their direction of travel. In areas with multiple viewing angles, consider using double-sided indications or tilted braces to preserve exposure from numerous instructions.

Furthermore, making sure that the indicators are not obstructed by other objects, equipment, or shelving systems is crucial. Clear sightlines aid prevent mishaps and improve general safety. By thoughtfully considering elevation and angle, you can dramatically enhance the efficiency of forklift safety signs, consequently fostering a safer workplace.

Signage Material and Durability

Choosing the ideal product for forklift safety and security signs is important for ensuring their longevity and effectiveness. In environments where forklifts operate, signs are usually revealed to severe conditions, including physical impacts, chemical spills, and differing temperature levels. Choosing long lasting products like aluminum, high-density polyethylene (HDPE), and polyvinyl chloride (PVC) can significantly enhance the indications' life-span.Furthermore, its lightweight nature facilitates easy installment and repositioning. PVC, on the various other hand, offers an excellent balance in between sturdiness and cost-effectiveness, making it a common selection for lots of industrial environments.

Moreover, the printing technique made use of on these products also plays a function in sturdiness. UV-resistant inks and safety laminates assist in protecting against fading and damage from sunlight and other ecological aspects. Complying with these factors to consider guarantees that forklift safety indicators stay visible and readable over extended periods, thus keeping a risk-free working atmosphere.

Making Certain Sign Exposure

While picking sturdy materials for forklift safety and security indications is necessary, ensuring their presence is just as crucial for preserving a risk-free environment. Effective presence can be accomplished via strategic placement, appropriate lighting, and making use of high-contrast shades. Indications must be placed at eye degree and in places where drivers and pedestrians are most likely to see them, such as at entrance points, junctions, and locations with high website traffic.Appropriate illumination is vital to guarantee that indicators are noticeable go now in all conditions. Mounting ample lights in poorly lit locations or making use of reflective materials on indications can significantly enhance visibility. Furthermore, high-contrast shades and vibrant font styles ought to be used to make the signs conveniently distinguishable from their environments. As an example, utilizing bright yellow histories with black text can ensure that the message sticks out.

Furthermore, preventing aesthetic clutter around the signs is necessary. A lot of indications in one area can bewilder and perplex people, minimizing the efficiency of each indicator. Clear, succinct messaging and ensuring indicators are complimentary from obstructions such as equipment or storage space things will even more boost their visibility and effectiveness, adding to a much safer office setting.

Normal Evaluation and Upkeep

Uniformity is key to preserving the efficiency of forklift safety and security indicators, making normal inspection and upkeep crucial. To ensure these indicators remain to interact important details clearly, they have to be consistently examined for wear and tear, fading, or obstruction. forklift safety signs. With time, exposure to the components and functional activities can degrade their presence and legibility, undermining their purposeA systematic assessment timetable more must be developed, straight from the source with checks conducted at normal intervals. During inspections, examine each indicator's problem, ensuring text and signs continue to be clear and dynamic. Any type of signs showing indications of damage or fading need to be without delay replaced. Additionally, make certain that indicators are not obscured by equipment, inventory, or other challenges.

Conclusion

Correct placement and visibility of forklift safety and security signs are essential in decreasing work environment crashes. Positioning signs at key locations such as entry and exit factors, facility intersections, and high-traffic storage space locations, while ensuring they are mounted at eye degree and angled in the direction of oncoming traffic, improves their performance.Report this wiki page